What is the difference between high and low frequency inverter?

Jun 27,2025

Jun 27,2025

Vevsun

Vevsun

What is the difference between Low Frequency Inverter and High Frequency inverter?

Inverter Introduction

Inverters are essential devices that convert direct current (DC) into alternating current (AC), widely used in solar power generation, UPS systems, electric vehicles, and other applications. Inverter can be divided into different types according to different characteristics, such as whether can be send the power to the grid or can't send power to grid can be divided into on grid inverter and off grid inverter. Depending on their operating frequency, inverters can be classified into two main types: low frequency (LF) inverters and high-frequency (HF) inverters.

This article explores the key differences between low frequency inverter and high frequency inverter, including their working principles, performance characteristics, advantages and disadvantages, typical applications, and future trends.

Quick Navigation

1. Working principle and key Features

2. Technical Comparison

3. Advantages and Disadvantages

4. Typical Applications

5. Future Trends

6. Selection Guide

1. Working Principle And Key Features

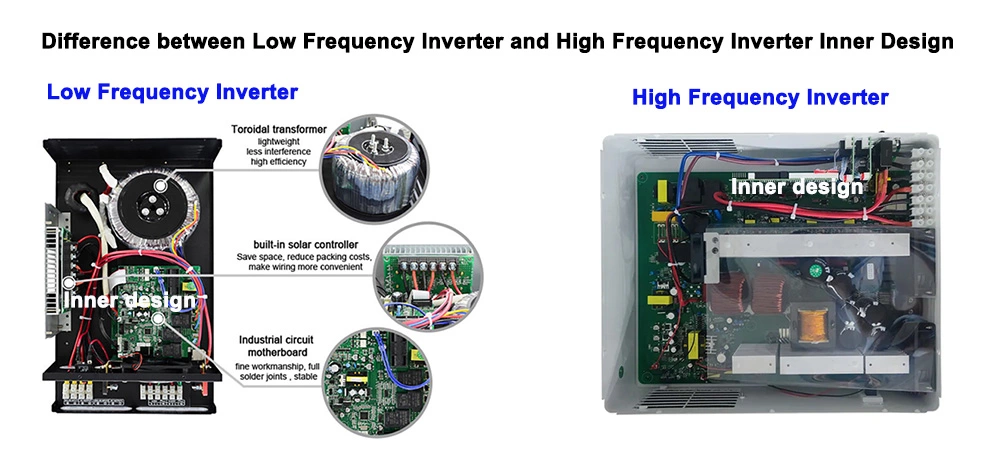

1.1 Low Frequency Inverters

Inverter circuit using power frequency transformer to boost voltage. It first inverts DC into power frequency low voltage AC; then boosts it into 220V50Hz AC through power frequency transformer for load use. Its advantage is simple structure. Because there is power frequency transformer between inverter power source and load, inverter operation is stable, reliable, and has strong overload capacity and impact resistance.

Key Features:

Compared with high frequency inverter, low frequency inverter has the following characteristics:

1. The weight and volume are much larger than high frequency inverter of the same power.

2. The efficiency is a little lower than that of high frequency inverter.

3. The reliability is generally higher than that of high frequency inverter, and it is not easy to break.

4. The load capacity, especially the impact load capacity, is better than that of high frequency inverter, and it can suppress the high harmonic components in the waveform.

5. The structure is relatively simple, and overload and short circuit protection are easier to make than high frequency inverter.

1.2 High-Frequency Inverters

The high-frequency inverter uses an inverter circuit that is boosted by a high-frequency transformer. It first uses high-frequency DC/DC conversion technology to boost the low-voltage DC through a high-frequency transformer, and then rectifies it into high-voltage DC that is usually above 360V through a high-frequency rectifier and filter circuit; finally, 220V AC is obtained through the inverter circuit for use by the load. Since the high-frequency inverter uses a small and light high-frequency magnetic core material, the power density of the circuit is greatly improved, so that the no-load loss of the inverter power supply is very small and the inverter efficiency is improved. Usually, the conversion efficiency of small and medium-sized high-frequency inverters can reach more than 90%.

Key Features:

1. High efficiency: High-frequency inverters can achieve high-efficiency power conversion through high-frequency switching technology. Its conversion efficiency is usually high and the loss is low when no-load.

2. Small size and light weight: Due to the use of high-frequency switching technology, high-frequency inverters can significantly reduce the size and weight of the transformer, making the overall equipment more compact and lightweight.

3. Wide voltage range: High-frequency inverters have a wide operating voltage range and can work stably under different voltage conditions.

4. High-precision voltage regulation: High-frequency inverters are equipped with high-precision voltage regulators to provide stable output voltage.

2. Technical Comparison

| Parameter | Line-Frequency Inverter | High-Frequency Inverter |

| Efficiency | Lower (80%-90%) | Higher (90%-98%) |

| Size/Weight | Large (heavy transformer) | Compact (lightweight design) |

| Cost | Higher transformer cost | Higher semiconductor cost |

| Reliability | High (robust against surges) | Depends on semiconductor lifespan |

| Harmonic Distortion | Higher (~5% THD) | Lower (<3% THD possible) |

| Power Range | Width power range (300W-40KW,etc.) | Low to medium power (<15 kW) |

| Voltage | Lower to Higher voltage 12V-384VDC | Normal model 24V/48V DC |

3. Advantages and Disadvantages

3.1 Low Frequency Inverter Pros & Cons

Advantages:

✔ High Overload Capacity – Handles sudden load spikes (e.g., motor startups).

✔ Reliable Electrical Isolation – Safer for industrial environments.

✔ Better Environmental Resistance – Performs well in harsh conditions (dust, high temperatures).

Disadvantages:

✖ Bulky and Heavy – Difficult to install in space-constrained areas.

✖ Lower Efficiency – More energy loss then high frequency inverter due to transformer heat dissipation.

✖ Higher Cost for Large Systems – Transformer expenses increase with power rating.

3.2 High-Frequency Inverter Pros & Cons

Advantages:

✔ High Power Density – Compact size (1/3 to 1/5 the weight of LF inverters).

✔ Faster Dynamic Response – Better for MPPT (solar tracking) and variable loads.

✔ Smart Control Features – Easier to integrate with digital control systems.

Disadvantages:

✖ More Complex Circuitry – Using high-frequency magnetic core materials to increase power density.

✖ Lower Surge Resistance – Sensitive to voltage spikes.

✖ Higher Cooling Requirements – High-frequency switching generates more heat.

4. Typical Applications

4.1 Low Frequency Inverters

Off-grid solar systems (long-term stability needed)

Industrial motor drives (cranes, compressors)

Marine & mining equipment (high-reliability environments)

4.2 High-Frequency Inverters

Residential solar PV systems (rooftop installations)

Electric vehicle charging (OBC)

Data center UPS systems (high efficiency required)

5. Future Trends

Hybrid Topologies – Combining HF and LF designs for better efficiency and reliability.

Wide-Bandgap Semiconductors (SiC/GaN) – Enabling higher switching frequencies (MHz range).

Digital Twin Control – AI-driven PWM optimization for reduced losses.

Modular Designs – Scalable HF inverter systems for flexible power expansion.

6. Selection Guide

Choose a Low Frequency Inverter If:

The load is highly inductive (e.g., motors).

Long-term heavy-duty operation is required.

The environment is harsh (high temperature, dust, humidity).

Choose a High-Frequency Inverter If:

Space and weight are critical (e.g., rooftop solar, EVs).

High efficiency and fast response are needed.

Smart grid integration is desired.

Case Study: Hybrid Microgrid System

In an island microgrid project, a line-frequency inverter was used for off-grid water pumps (handling surge loads), while a high-frequency inverter managed the solar PV array. A hybrid control system improved overall efficiency by 12%.

Conclusion

Both line-frequency and high-frequency inverters have distinct strengths and weaknesses. The choice depends on factors like power requirements, environmental conditions, efficiency needs, and cost constraints.

As technology advances, hybrid designs and wide-bandgap semiconductors will further bridge the gap between these two inverter types, offering better performance across various applications.

Home

Home

The Ultimate Guide to Choosing the Right PV Inverter.

The Ultimate Guide to Choosing the Right PV Inverter.  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address